Plant Integrate iT Batch Cockpit: The entry point to integrated batch analysis

To guarantee a constant high level of economic prosperity, industrial businesses must optimise, automate and customise their production processes while at the same ensuring outstanding product quality. The large amounts of data that arise are business critical for the companies and must therefore be available at all times. The strategic application of this data is becoming an increasingly important factor in the field of production – the key words here are predictive maintenance and flexible production processes.

In modern-day manufacturing industry: High data availability during production is viewed as a real competitive advantage over every rival.

Transparency is the order of the day when it comes to gaining a precise overview of production activities and optimising them extensively. Effective and efficient processes can only be achieved when you are well informed of the current plant status regarding capacities, materials and costs - at all times. The ability to know which batch is produced when, how and where and at which level of quality is thus elementary.

Yet the reality is very different for many plant operators: The large volumes of data generated during production proceedings often place an excessive burden on staff – correlations remain undetected and potentials unused. There is a lack of both time and options to deal with the flood of information effectively.

Maximum data sovereignty

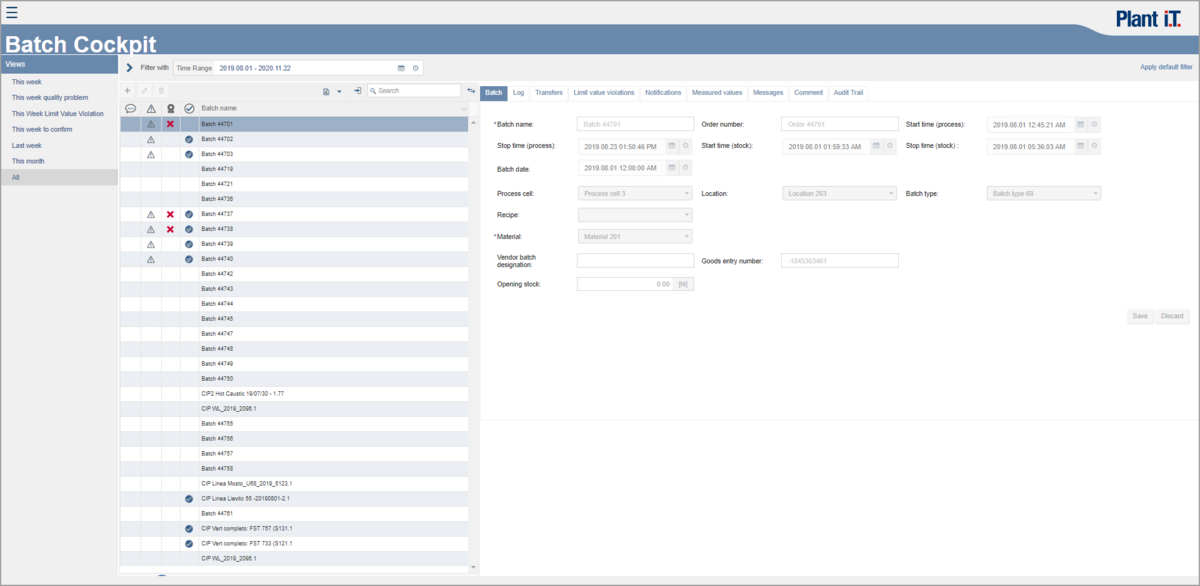

The add-on Plant Integrate iT Batch Cockpit from ProLeiT is a software solution for greater transparency and more effective plant utilisation in the process industry. The add-on is designed for evaluating, processing and validating production data. In addition, it is possible to post-process manually recorded data and thus correct any errors directly. As a result, time-consuming and cost-intensive data corrections in higher-order systems are no longer required.

Freely definable filters, for example “time period”, “batch type” or “status”, enable convenient and targeted analysis of the recorded production data. Moreover, off-specification batches can be tracked. Plant operators can view the data that is most valuable to them.

Audit Trail – complete traceability

The Audit Trail function provided by Batch Cockpit allows you to review and analyse batch records. As a result, all changes can be traced in full – both in the front end and in the database. Audit Trail displays, among other things, information about the user, the applied end device and when the change was executed. This guarantees complete traceability at all times. The add-on Plant Integrate iT Batch Cockpit includes the following functions:

- Post-processing of manually recorded production parameters

- Subsequent input of non-automated processes

- Flexible data analysis via freely definable filters

- Analysis of the batch record using the Audit Trail function

- Seamless connection to the MES solution Plant Integrate iT

Batch Cockpit from ProLeiT represents the entry point to integrated batch analysis. Thanks to seamless integration in other functions of our MES solution Plant Integrate iT, all the data can be further processed and prepared productively.