Production data management with Plant Acquis iT

The latest standards

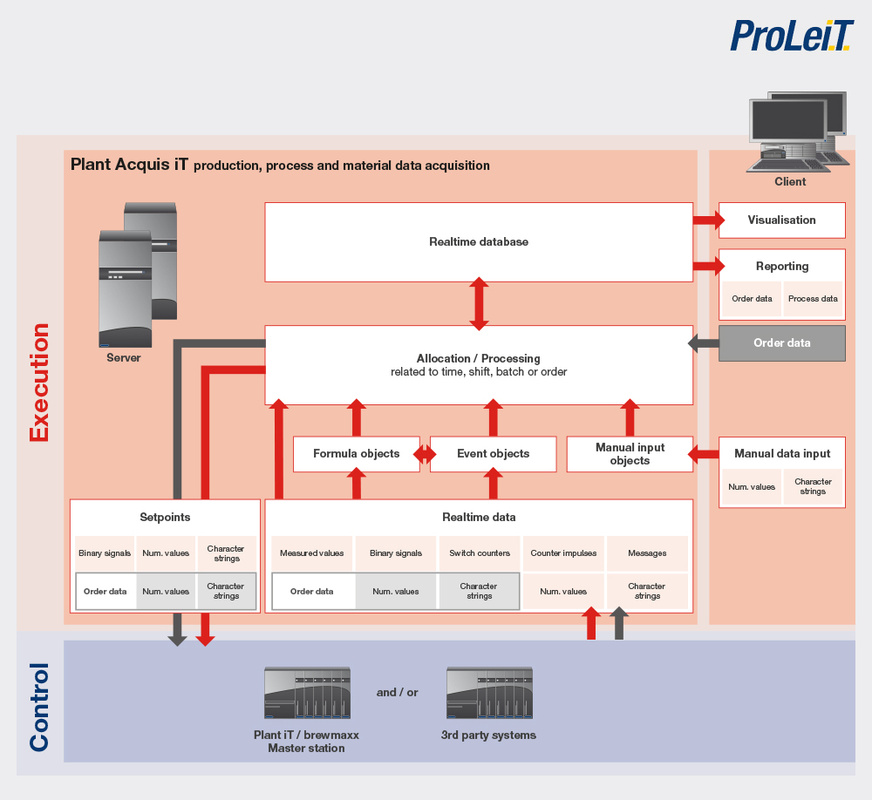

Plant Acquis iT has been tailored to the specific requirements of the Weihenstephan Standards for bottling plants. In addition to using OPC or the driver-based connection of subordinate controllers, Plant Acquis iT also provides an individual communication channel.

Materials management

Plant Acquis iT meets the latest requirements of product tracing by providing functions for material-related production data management. Combined with Plant iT material, it is thus possible to generate booking records for material transactions via specially prepared event objects. Functions, such as inventory management and batch tracing, are therefore also available for processes not directly controlled by Plant iT components.

Open for extensions

Thanks to its open architecture, Plant Acquis iT allows application-specific extensions, e.g. Excel-based reporting. Microsoft Excel accesses the central database via system-internal standard interfaces, thus enabling the flexible creation of reports. Advantages:

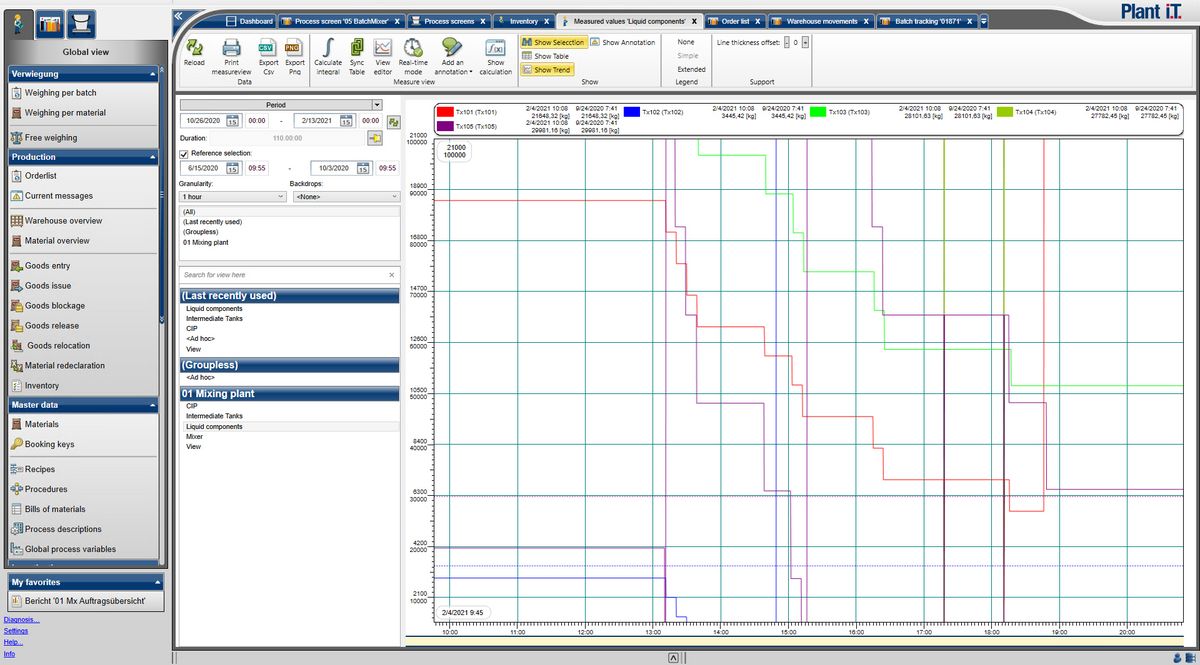

- Use of standard Microsoft Excel evaluation and presentation functions for creating tailored reports based on the recorded production data

- Users familiar with Microsoft Excel can carry out individual adjustments.

Alternatively, the system also provides open interfaces for integration into HTML or XML-based reporting.

Furthermore, Plant Acquis iT also offers a suitable basis for bottling and packaging management and can provide the following functionalities:

- Line-related order lists, incl. data exchange with subordinate automation systems

- Plant monitoring

- Fault analysis and performance analysis (e.g. according to OEE).

These functions effectively support the operator when optimising plant performance.