How does OEE work?

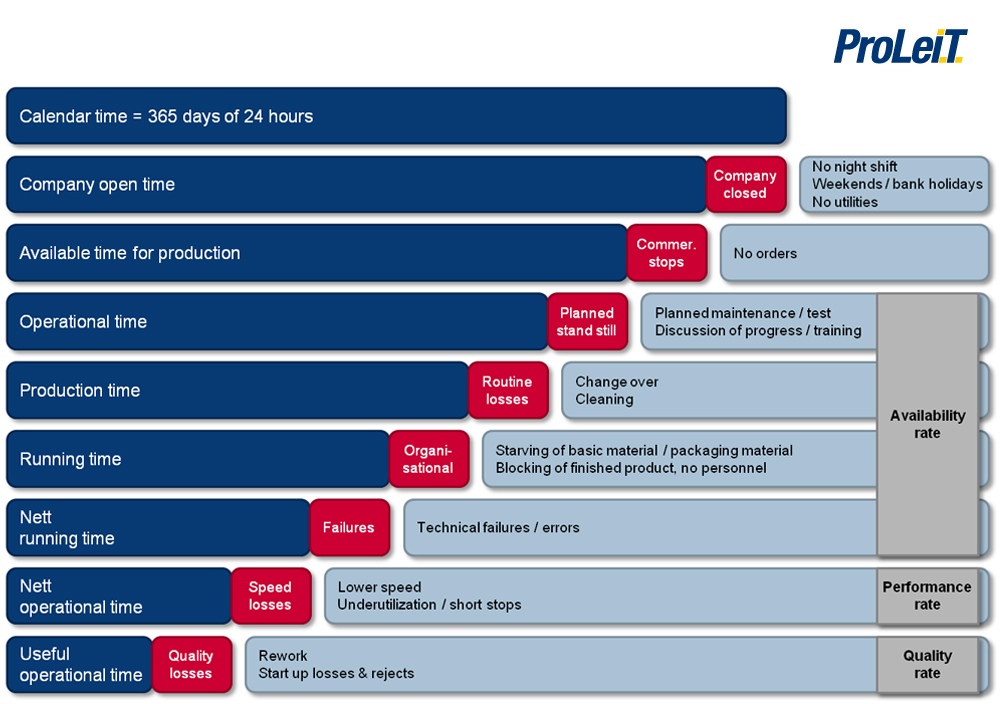

The methodology for the determination of key figures created by Japan Institute of Plant Maintenance was developed over many years in the course of the TPM concept development (TPM: Total Productive Maintenance) and is the benchmark for the value added ratio of a plant. The OEE of a plant has three key components:

- Availability factor

- Performance factor

- Quality factor

The formula for calculating the OEE is:

OEE = availability in % x performance in % x quality in %

OEE time calculation

The OEE key figure is primarily used to identify unplanned plant losses. Therefore, the planned stoppages are subtracted from the actual calendar period (24/7). Examples of unplanned stoppages are:

- No occupancy/allocation

- Planned maintenance downtime

- Breaks

- Strikes

- etc.

The remaining operating period is then the basis (100%) for the OEE calculation. The performance, availability and quality losses are then subtracted from this 100 percent.