MES - standards

The standards of various organisations, such as MESA (Manufacturing Enterprise Solutions Association) or NAMUR (Standard Working Group for Measurement and Automatic Control Systems), have contributed greatly to a standardised definition of MES. A key standard for manufacturers, users and system integrators is DIN EN 62264 based on IEC 62264 (Enterprise Control System Integration) of the ISA (Instrumentation, Systems, and Automation Society). The international standard focuses on the continuous transfer of information between manufacturing systems and enterprise systems.

ZVEI

In collaboration with several MES providers - including ProLeiT - the working group of ZVEI (Central Association of the German Electrical and Electronic Engineering Industry) has published the brochure “Manufacturing Execution Systems (MES) – Industry-Specific Requirements and Solutions”. Whilst taking the various industry-specific requirements into account, this brochure provides an overview of currently available and realisable MES solutions. The IEC 62264 standards, frequently referred to as S95, formed the basis for this independent consideration of the MES functions. The brochure explains key items of terminology and structuring of S95, thus providing an excellent guide to understanding MES.

Thanks to our collaboration with ZVEI, we use the MES brochure to ensure clear and open dialogue with our customers. The presented model for production plant management is extremely useful when planning MES projects. For example, this model divides a company into MES-relevant areas:

- Maintenance management

- Production management

- Quality management

- Warehouse and inventory management

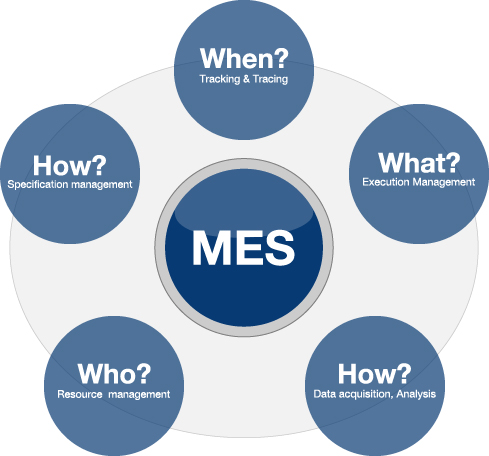

In accordance with the generic activity model, which illustrates individual interaction between the various MES areas, we often use the five-question model (see the following illustration) to define relevant activities.

The resulting answers generally provide the necessary data for the effective planning of MES projects. Underpinned by our extensive project experience, we are able to realise complex projects, across several locations, within a defined time schedule – without having to stop production.

For more information on realised projects, please contact us here.