Energy Management step by step

Thanks to the integration of the energy management system in our process control systems, acquisition, analysis and optimisation are executed on the same platform as the actual process control. This results in considerable benefits in real conditions:

- Integrated and standard data pools.

- Familiar analysis tools (no training necessary for new software).

- Same user interface for process and energy management.

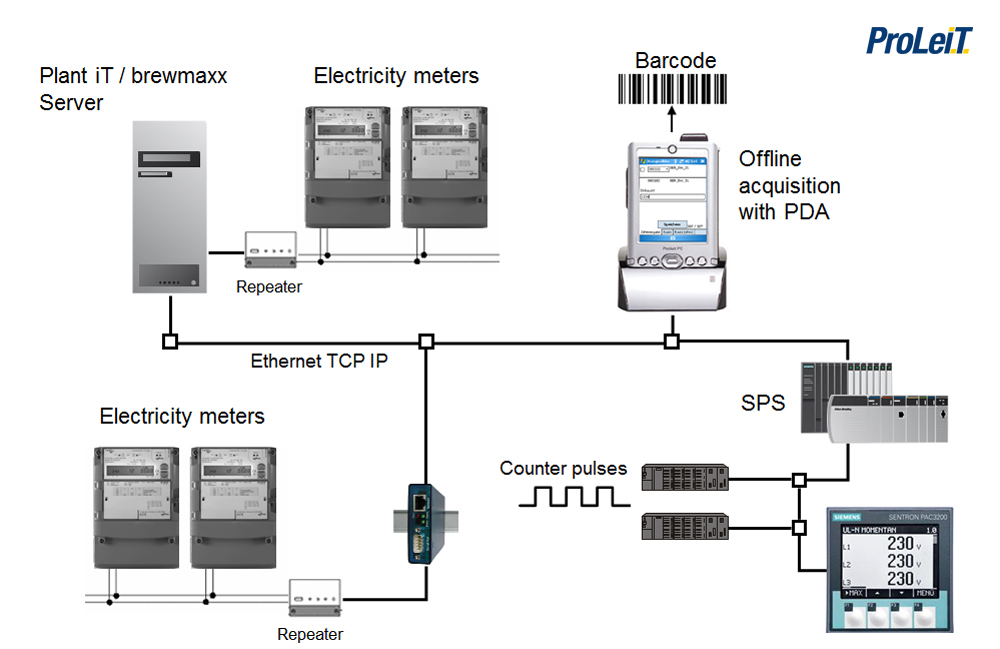

Step 1: Energy data acquisition

The first step when implementing energy management solutions is the acquisition of all the information (e.g. consumption data) usually provided by a process control system. In existing plants, it is quite often the case that not all the energy meters are actually linked to the process control system and must, therefore, be recorded offline.

Basically, all the meters for

- primary energy sources (electricity, oil, gas, water) and

- secondary energy sources (heating steam, sterile steam, hot water)

must be recorded. Furthermore, the consumption of other media, e.g. cooling agents or CO2, must also be captured and integrated into the common data pool.

Acquisition of offline meters

In order to realise the acquisition of consumption data for existing but not connected counters, we provide an acquisition system with state-of-the-art PDAs. The PDAs to be captured offline are identified via barcode labels using handheld scanners. Manual input is checked for plausibility prior to saving.

Data acquisition via PDA Scanner

The procedure for offline data acquisition via PDAs may be as follows:

- Select a route from several predefined routes

- Display the next location

- Scanning: Identify a location (where?)

- Enter a meter value

- Execute plausibility checks

- Display the next location or select the next meter

- Transfer data to the database