Why energy management?

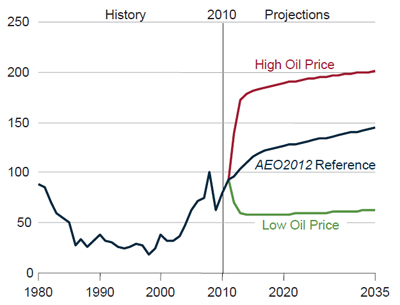

Quite simply because of the high energy costs and the common assumption that the price of electricity, oil and gas will continue to rise in the future. For example, the German Federal Statistical Office has forecast a 7.2% rise in energy costs in 2012 compared to the previous year. When considering global studies on future energy cost developments, it becomes quite clear that a reduction in costs for primary and secondary energy sources will play an increasingly important role for the optimisation of manufacturing costs.

Many manufacturers are therefore asking themselves the question as to whether and how they can continue to produce goods cost efficiently in the future. The transport and industry sector are obviously the worst affected due to their enormous demand for energy. One solution to reducing energy consumption is intelligent Energy Management Systems (EnMS). The positive effects of these systems on the energy balance of a company are felt quite soon after implementation. EnMS enable manufacturing companies to recognise and make the most of existing potentials in order to improve energy efficiency. In other words, weak points can be detected and energy costs cut significantly. In the meantime, energy management systems have developed into a direct competitive advantage.

Energy management systems for the process industry

The implementation of energy management systems usually starts with an on-site appraisal and feasibility study at our customers’ premises. Depending on the existing infrastructure and IT systems, we develop, together with our customers, precise measures to reduce energy consumption step-by-step without negatively affecting current production processes and product quality.

The implementation of an EnMS is a continuous process which incorporates the following steps:

- Development of an integrated network for the acquisition of all energy consumption data

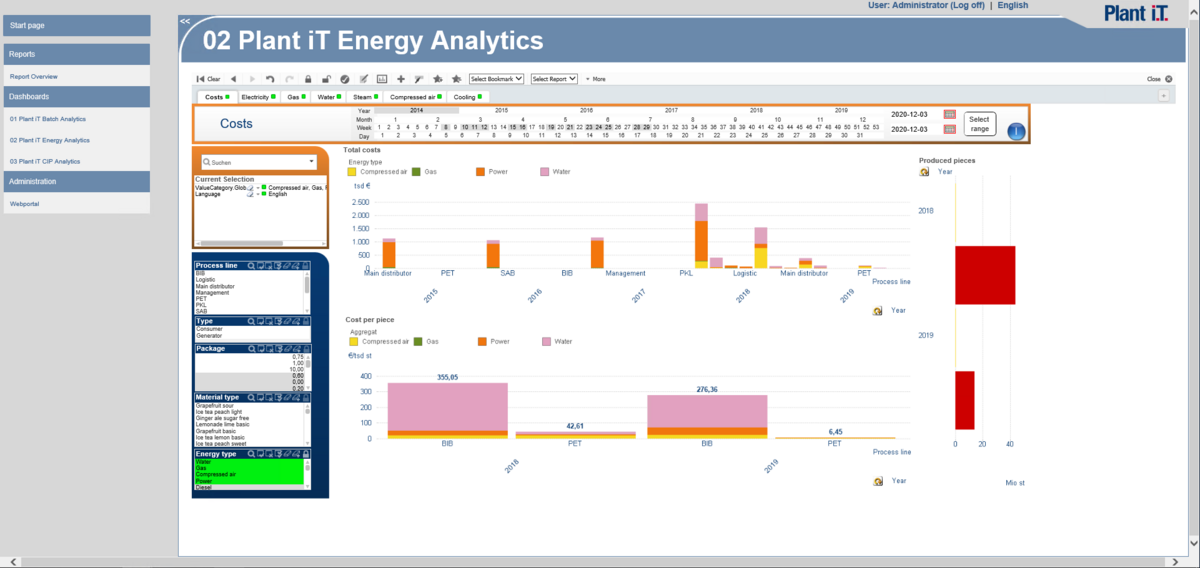

- Creation of consumption analyses based on various parameters with a detailed analysis of critical devices or plants, as well as peak load analyses

- Development of a simple energy management solution with automatic load shedding without process coordination

- Implementation of an integrated energy management system with automatic and technologically coordinated load shedding

The following pages provide a brief overview of EnMS – which solutions we provide and how they are realised.