Plant Batch iT MWS: The weighing assistant for manual weighing processes

Adding materials manually is a task that is regularly needed in the process industry. These may be anything from small quantities for laboratories to quantities recorded using only platform scales. Potential sources of error at this stage are basically due to the fact that weighing orders are written down by hand and safety regulations are not met. Inefficient weighing processes and off-specification batches caused by erroneous additions additionally lead to reduced quality and a notable loss of time and raw materials.

Intelligent weighing assistant for a high level of productivity and quality

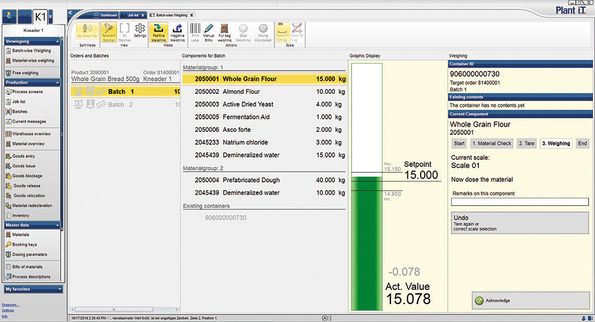

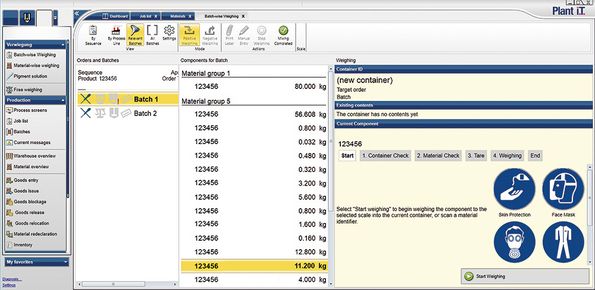

ProLeiT's new Manual Weighing System (MWS), an add-on for the modular process control system Plant iT, delivers an intelligent weighing assistant that enables the clear processing of bills of material while visually and reliably guiding operators through the weighing process aided by five colour grades. In order to offer the best possible support for processes at the operating station, the application contains workflow data, including, e.g., information about required protective clothing or how to handle certain materials.

Furthermore, the MWS helps operators select the most suitable scales depending on the stipulated weighing and tolerance range. After completing a weighing process, a label can be created for the packaging. The barcode of this label integrates all relevant information about the order data, weighed components, including quantities, and, if necessary, handling and danger symbols.

The add-on Manual Weighing System (MWS) includes the following functions:

- Reliable visual support for the manual weighing process

- Automatic selection of suitable scales

- Greater safety for component additions

- Integration of quality management

- Customer-specific functions possible

Optimisation potential on all levels

The Manual Weighing System from ProLeiT helps to optimise weighing processes at every level of the process industry: Production managers profit from the traceability of the applied materials and can rely on improved safety standards due to the reliable operator guidance. Moreover, utilisation of barcodes and scanner ensures a particularly high level of safety when adding components. The work of staff at operating stations is significantly aided by clearly structured visualisation techniques and stored workflows, while the complete overview of all existing production orders enhances rationalised work practices. The quality management system can also play a greater role in optimising weighing processes by customising workflows, thus guaranteeing adherence to customer-specific regulations and instructions at all times.